Whether your application is high volume and heavy duty or low speed with high accuracy we can deliver a solution with a wide range of high speed coaxial and conventional.

Laser cladding equipment manufacturer.

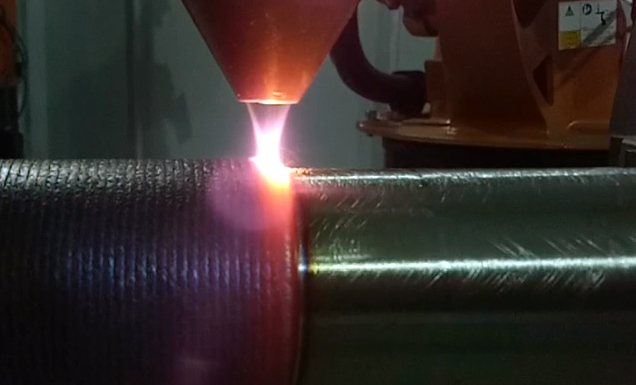

For example the construction equipment industry applies this technology to their products to increase wear resistance and keep equipment in service longer.

When it comes to laser cladding the equipment alone is not enough to produce the true value of a kondex laser clad part.

The emergence of laser cladding equipment market is attributed to its designing and usage ability that has revolutionized the maintenance and repair time for respective material surface of machines.

Dbch 2500 2 5 deep bore clad head robust 4kw laser cladding nozzle compatible with powder wire or hotwire learn more dbch 1500 1 5 deep bore clad head robust 1800 watt laser cladding nozzle compatible with powder wire or hotwire learn more.

Laser welding differs fundamentally from laser cladding in that it does not require a filler material.

Robust 4kw laser cladding nozzle compatible with powder wire or hotwire learn more.

Like laser cladding laser welding also produces a minimal heat affected zone and little thermal distortion.

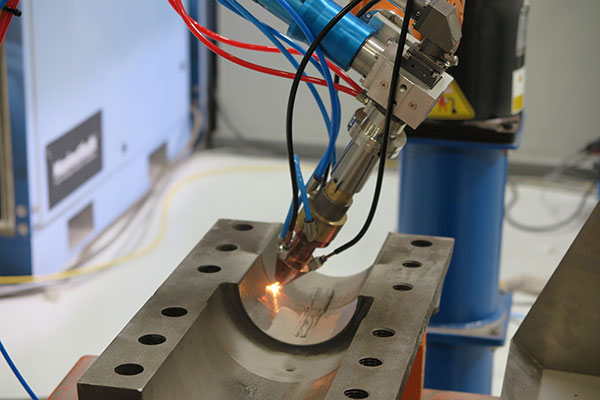

Lct works closely with leading global cladding head manufacturers enabling us to offer laser equipment optics and cladding heads that are required for specific applications.

Laser cladding machine laser cladding equipment laser welding machine laser welder.

For applications that require joining dissimilar materials manufacturers can include an interlayer with ir absorbing qualities.

Repair system offers from repair system manufacturers suppliers exporters wholesalers related keywords.

We further support you with laser cladding application development and support training and production ramp up services.

Laser beam was transmitted focused and detected by the optical system of co2 laser cladding equipment.